Breaking Down the Process of Display LED Transparent Manufacture: A Comprehensive Guide

Introduction to Display LED Transparent Manufacture

Display LED Transparent technology represents a significant advancement in digital displays, merging high resolution with an undistracted view. This blog post aims to unravel the complexities of Display LED Transparent manufacture, discussing the technologies involved, industry standards, and the future outlook.

What is Display LED Transparent Technology?

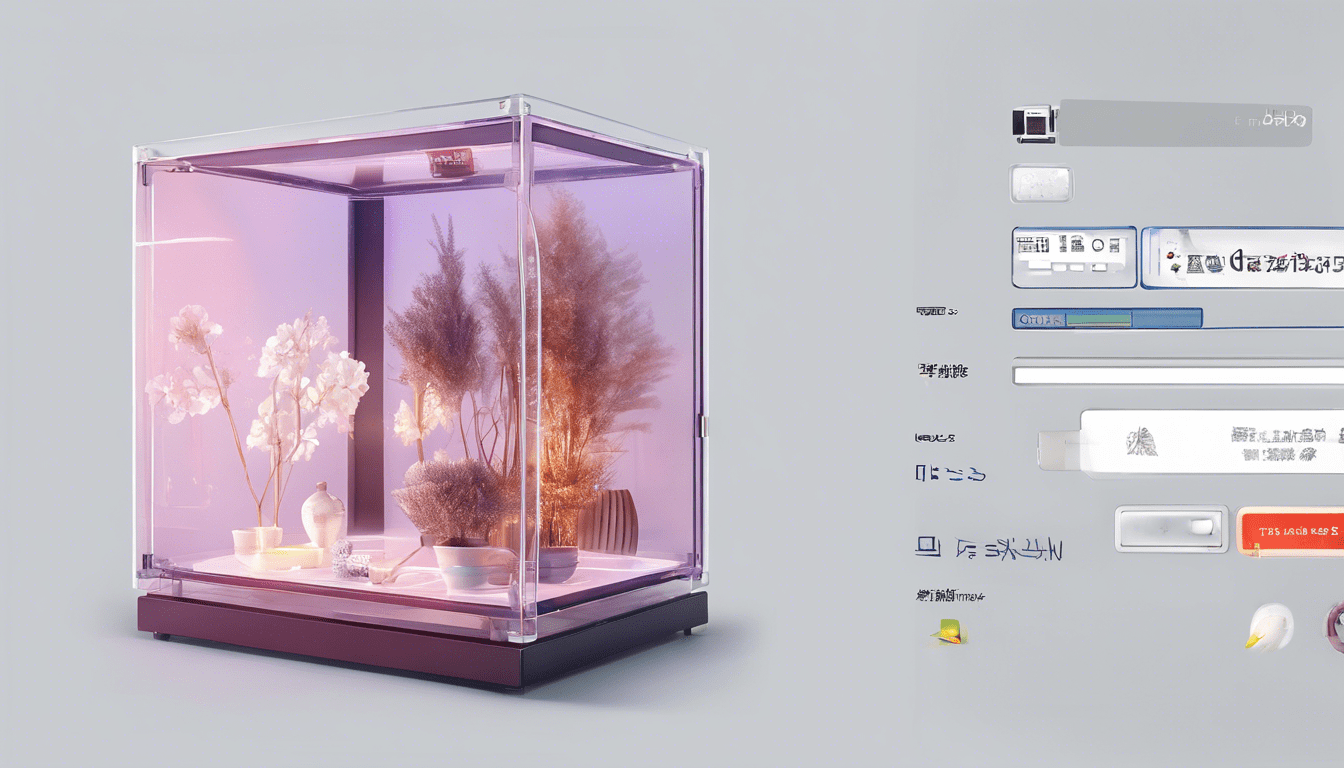

Display LED Transparent refers to screens that are semi-transparent and can display dynamic images while allowing viewers to see through them. This technology is widely utilized in advertising, retail, museums, and architectural design.

Key Components of Transparent LED Displays

- LED Strips: These strips contain multiple small LEDs that emit light to form an image.

- Transparent Substrate: Usually made from glass or acrylic, offering the transparency aspect.

- Control System: A complex system that manages the input image, brightness, and color balance.

- Power Supply: Ensures adequate power is provided to all display components.

The Steps in Display LED Transparent Manufacture

Manufacturing transparent LED displays involve multiple intricate steps to ensure high quality and functionality.

Step 1: Material Selection

The selection of transparent substrates and high-quality LEDs sets the foundation for the entire manufacturing process.

- Transparent Substrates: Selection between glass and acrylic based on application and cost.

- LED Quality: Ensuring LEDs have consistent color and brightness levels.

Step 2: Assembly of LED Modules

- Mounting LEDs: LEDs are systematically mounted on transparent strips or panels.

- Wiring: Detailed wiring ensures each LED receives the correct input.

Step 3: Testing and Calibration

- Initial Testing: Verifying that all LEDs function correctly.

- Calibration: Adjusting brightness and color uniformity for high-quality displays.

Step 4: Integration with Control Systems

- Control Software: Embedding software that manages display functions.

- Network Configuration: Configuring the display for remote management if necessary.

Step 5: Quality Assurance

- Final Testing: Comprehensive tests to ensure visual fidelity and reliability.

- Inspection: A thorough inspection to identify any physical or functional defects.

Step 6: Packaging and Shipping

- Protective Packaging: Ensuring the displays are safely packed to prevent shipping damage.

- Logistics: Coordinating efficient and safe transportation to customers.

Applications of Transparent LED Displays

Transparent LED displays have diverse applications, providing a blend of aesthetics and functionality.

Retail and Advertising

Transparent displays are used in storefronts and advertising screens, offering dynamic content while allowing visibility inside the store.

Architectural Design

Used in modern architecture, these displays can be integrated into building facades to show interactive content.

Museums and Galleries

Displays can present historical information and multimedia content without overshadowing the physical exhibits.

Product Presentations

Used in trade shows and product launches, transparent displays provide an immersive experience.

[mid-article insert shortcode]

Future Trends in Display LED Transparent Technology

As the market for transparent LEDs grows, new trends are emerging that will shape the industry’s future.

Improved Transparency

Advancements in materials science will lead to even greater levels of transparency without compromising display quality.

Enhanced Resolution

Ongoing improvements in LED technology will yield higher resolutions, providing sharper and more vibrant displays.

Flexible Displays

The development of flexible substrates will allow transparent LEDs to be used on curved surfaces, expanding their applications.

Internet of Things (IoT) Integration

Future displays will be increasingly integrated into the IoT, allowing for more interactive and networked applications.

Challenges in Manufacturing Transparent LED Displays

Manufacturing transparent LED displays is not without its challenges, which include:

Material Quality

Ensuring consistent quality in substrates and LEDs, as imperfections can degrade transparency.

Complex Assembly

The precision required in mounting and wiring LEDs increases the complexity of manufacturing.

Cost Management

Balancing high-quality production with cost efficiency to make transparent displays accessible to a broader market.

Industry Standards and Regulations

Complying with industry standards ensures that transparent LED displays are safe, reliable, and of high quality.

Safety Standards

All displays must meet industry safety standards to prevent electrical hazards and ensure long-term reliability.

Environmental Regulations

Manufacturers must comply with environmental regulations, including the disposal of electronic waste and the use of eco-friendly materials.

Quality Certifications

Certifications such as ISO and CE mark ensure adherence to international quality and safety standards.

Case Studies: Successful Implementations

Examining real-world applications provides insights into the impact and effectiveness of transparent LED displays.

Retail Giant’s Storefront

A leading retail brand integrated transparent LED displays in their storefront windows, increasing customer engagement and foot traffic.

Architectural Showcase

A landmark building used transparent displays in its façade, making it an interactive landmark on the cityscape.

Museum Exhibition

A renowned museum implemented transparent LED displays that seamlessly presented multimedia alongside traditional exhibits, enhancing visitor experience.

Conclusion

Display LED Transparent manufacture is a complex yet rewarding process, providing innovative solutions across various industries. As technology continues to evolve, the applications and efficiencies of transparent LED displays will expand, making them a staple in modern digital displays.