Display Transparent LED Manufacture: The Ultimate Guide

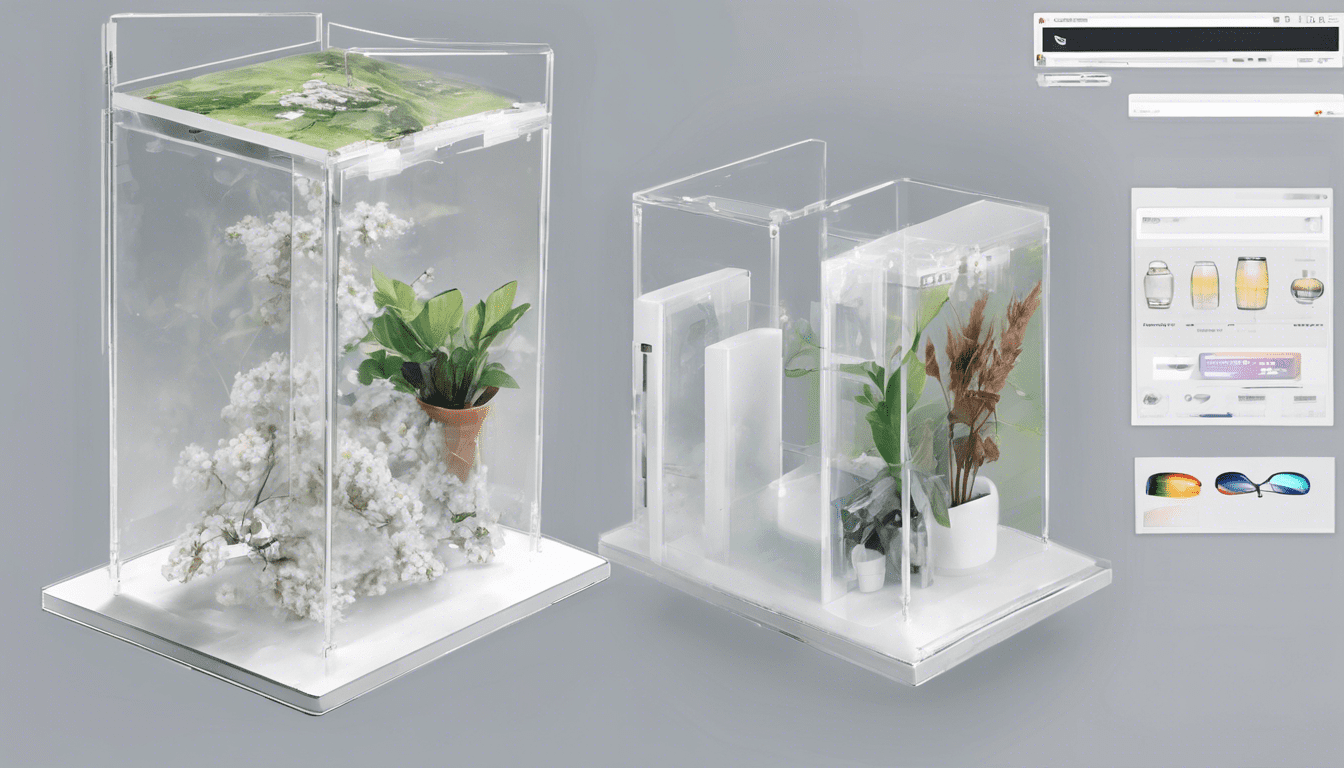

Introduction to Transparent LED Displays

Transparent LED displays are revolutionizing the way we present visual content. They offer remarkable transparency, allowing viewers to see through them while displaying high-definition content. This innovative technology is becoming increasingly popular in retail, architectural, and advertising applications.

What is a Transparent LED Display?

Transparent LED displays are advanced digital screens that display images and video content while maintaining a high degree of transparency. They are often used in store windows, glass partitions, and other installations where visibility and aesthetics are crucial.

How Does Transparent LED Display Work?

The technology behind transparent LED displays involves micro LED lights embedded within a clear, transparent substrate. The LED lights emit light and colors independently, creating vibrant images and videos without obstructing the view behind the display.

Applications of Transparent LED Displays

- Retail and Shop Windows: Transparent LED displays are perfect for retail environments as they both attract customers and allow them to see inside the store.

- Corporate Offices: Used in glass partitions for meeting rooms, they facilitate dynamic presentations without losing the transparent aesthetics.

- Automotive Industry: They are used in car windows and windshields for heads-up displays.

- Museum and Exhibitions: Enhances exhibits while maintaining a clear view of objects on display.

Components of Transparent LED Displays

1. LED Chips: The core component that emits light.

2. PCB (Printed Circuit Board): Hosts the LED chips and manages electrical connections.

3. Power Supply: Provides the necessary electricity to the display components.

4. Control System: Manages the display content and its settings.

5. Transparent Substrate: The clear material hosting the LEDs, ensuring transparency.

The Manufacturing Process of Transparent LED Displays

Manufacturing transparent LED displays involves several intricate processes:

1. Design and Engineering

The first step involves designing the layout and structure of the LED display. Engineers need to ensure the right balance between LED placement and transparency.

2. Material Selection

Choosing high-quality transparent substrates and efficient LEDs is crucial. The materials must ensure durability, clarity, and efficient light emission.

3. LED Chip Production

Manufacturers produce LED chips in clean room environments to ensure high quality and efficiency. The chips are then tested for performance and consistency.

4. PCB Manufacturing

PCBs are designed and produced to suit the specific layout requirements of the display. This step includes embedding circuits that will drive the LED chips.

5. Assembly

The transparent substrate, PCB, and LED chips are carefully assembled. Precision is critical to ensure the LEDs are aligned correctly while maintaining transparency.

6. Testing and Quality Control

Each transparent LED display undergoes rigorous testing for brightness, color accuracy, transparency, and durability. Quality control ensures that each unit meets the required standards.

Advantages of Transparent LED Displays

- High Transparency: Maintains visibility while displaying content.

- Energy Efficient: Consumes less power compared to traditional displays.

- Lightweight and Thin: Easy to install and integrate into existing structures.

- Versatile: Suitable for various applications and environments.

- Dynamic Content: Displays animations, videos, and stunning visuals.

Challenges in Manufacturing Transparent LED Displays

- Balancing Transparency and Brightness: Ensuring that both visibility and display quality are optimal.

- Durability: Making a robust product that can withstand various environmental conditions.

- Complex Assembly: Requires precision engineering and technology.

- Cost: Higher production costs compared to traditional LED screens.

Future Trends in Transparent LED Display Technology

1. Enhanced Resolution

As technology advances, we can expect even higher resolution displays, providing crisper and more vibrant visuals.

2. Larger Sizes

Manufacturers are working on producing larger transparent LED displays suitable for more extensive installations and more impactful visuals.

3. Flexible and Curved Designs

Innovations in flexible substrates may lead to transparent LED displays that can be curved or folded, offering more design possibilities.

4. Integration with Smart Technologies

Integration with AI and IoT devices will provide smarter and more interactive display solutions.

Case Study: Successful Transparent LED Display Installation

In 2021, a leading retail brand revamped its flagship store by installing large transparent LED displays in its windows. The displays attracted more foot traffic and enhanced the store’s modern, high-tech aesthetic. The installation resulted in a 30% increase in store visits and a 20% boost in sales within the first quarter.

Conclusion

Transparent LED displays are an innovative and versatile visual solution offering numerous advantages over traditional screens. Their transparent nature, combined with high display quality, makes them ideal for various applications, from retail to corporate environments. As technology continues to advance, the future of transparent LED displays looks promising, with exciting possibilities in resolution, size, flexibility, and smart integration.