Revolutionary Guide to Full Color LED Digital Display Board Manufacture

Introduction to Full Color LED Digital Display Boards

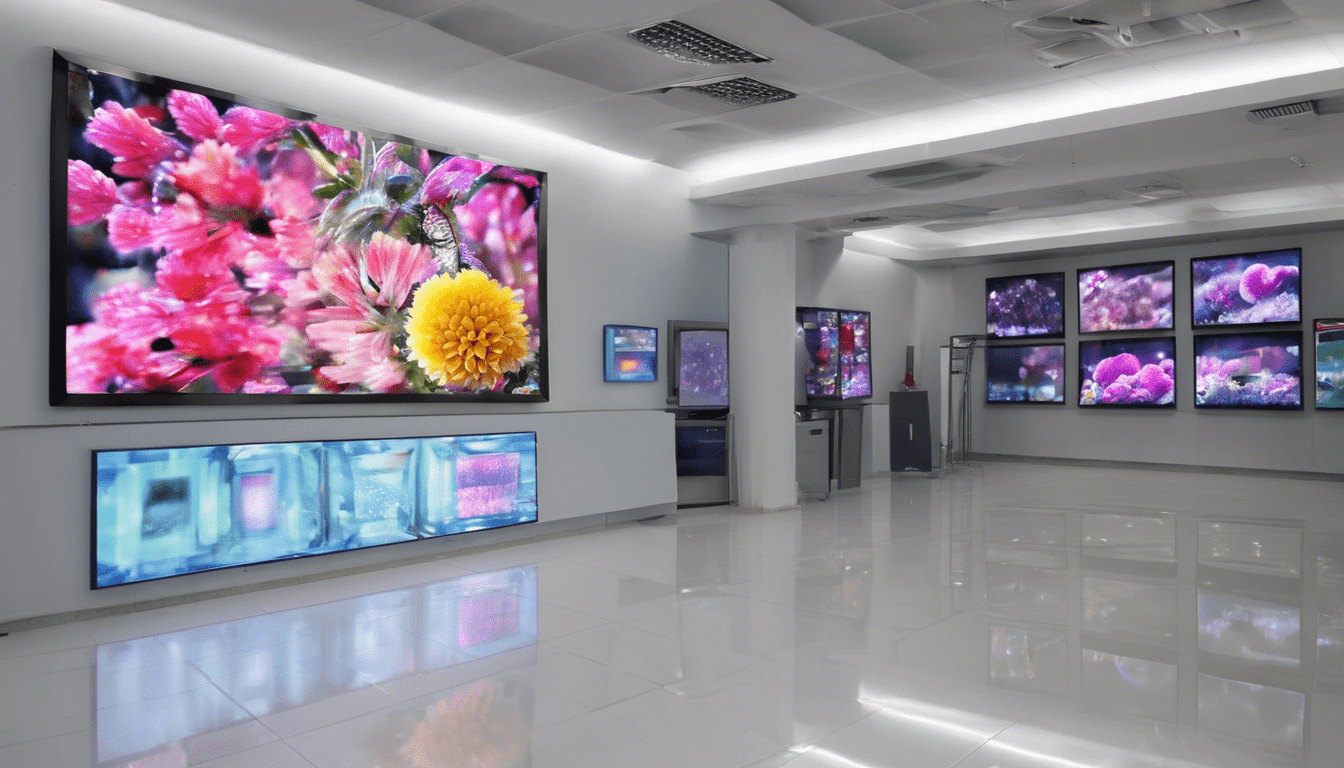

Full-color LED digital display boards have transformed the way we convey information and advertising content. From vibrant billboards to dynamic indoor displays, these boards offer unparalleled brightness and clarity. This guide delves into the intricacies of their manufacture, ensuring you understand the complete process and its significance.

What Is a Full Color LED Digital Display Board?

A full-color LED digital display board is a type of electronic display that uses light-emitting diodes (LEDs) to portray vibrant images, videos, and texts. These boards are commonly used for commercial advertising, information display in public spaces, and even in sports arenas.

Components of Full Color LED Digital Display Boards

To understand their manufacture, it’s essential to grasp the core components:

- LED Modules: The building blocks of the display. They consist of tiny LED chips arranged in a grid.

- Control System: Manages the signals and images displayed on the board.

- Power Supply: Provides the necessary power for the LED modules.

- Casing: Encases the LEDs and protects the internal components from external factors.

- Cooling System: Ensures the board remains at an optimal temperature.

Manufacturing Process of Full Color LED Digital Display Boards

The manufacturing process can be intricate. Below, we break down each step:

1. Design and Planning

Every LED display starts with meticulous design and planning. Engineers use CAD software to create blueprints, ensuring accurate dimensions and placement of each component.

2. Sourcing Quality Materials

The quality of materials directly affects the durability and performance of the display board. Key materials include:

- High-quality LED chips: Ensuring efficient luminosity and longevity.

- Robust casings: Often made of aluminum or other durable materials.

- Reliable power supplies: Stability is crucial for non-stop performance.

3. Assembly of LED Modules

LED modules consist of numerous tiny LED chips. Automated machines precisely place these chips onto a printed circuit board (PCB). The arrangement is critical to achieving desired brightness and color accuracy.

4. Integration of Control Systems

The control system is integrated into the LED board to ensure seamless communication between the display and the input source. Advanced control systems even allow real-time content updates.

5. Testing and Quality Assurance

Before shipping, rigorous testing is conducted:

- Brightness and Color Calibration: Ensuring uniformity across the display.

- Stress Testing: To check durability against various environmental factors.

- Performance Testing: Ensuring smooth operation under different conditions.

Full Color LED Digital Display Board Applications

These boards offer versatile applications across various industries:

- Advertising: Widely used for billboards, offering dynamic and eye-catching displays.

- Information Displays: Deployed in airports, train stations, and malls for real-time information sharing.

- Concerts and Events: Creating immersive visual experiences.

- Retail: Enhancing store interiors with dynamic promotional content.

Challenges in Full Color LED Digital Display Board Manufacture

Despite their benefits, there are challenges in the manufacturing process:

- Heat Dissipation: Maintaining optimal temperatures is critical to avoid damage.

- Power Consumption: Balancing brightness with energy efficiency.

- Weather Resistance: Ensuring outdoor displays can withstand extreme conditions.

- Pixel Density: Achieving high resolution while maintaining cost-effectiveness.

Latest Trends in Full Color LED Digital Display Boards

The industry continually evolves with technological advancements:

- MicroLED Technology: Offering higher brightness, more vivid colors, and better energy efficiency.

- Flexible Displays: Expanding the possibilities in design and application.

- Higher Resolutions: As 4K and even 8K resolutions become more accessible.

- Smart Integration: Incorporating IoT for smarter, more adaptive displays.

Future Prospects of Full Color LED Digital Display Boards

The future looks vibrant for LED digital displays with potential advancements in AI-driven content management and integration with other smart devices. The market is also expected to grow as costs decrease and technology becomes more accessible.

Case Study: Successful Implementation

Let’s explore a real-world example – Times Square in New York City. The dynamic LED displays here are a testament to their effectiveness. With millions of passing viewers, advertisers capitalize on the high engagement, showcasing everything from commercials to public service announcements.

Conclusion

The manufacture of full-color LED digital display boards is a fascinating blend of engineering, design, and technological innovation. From sourcing quality materials to rigorous testing, every step ensures the final product is both durable and visually captivating. As technology advances, these displays will only become more integral to our communication and advertising landscapes.