The Ultimate Guide to LED Display Wall Manufacture

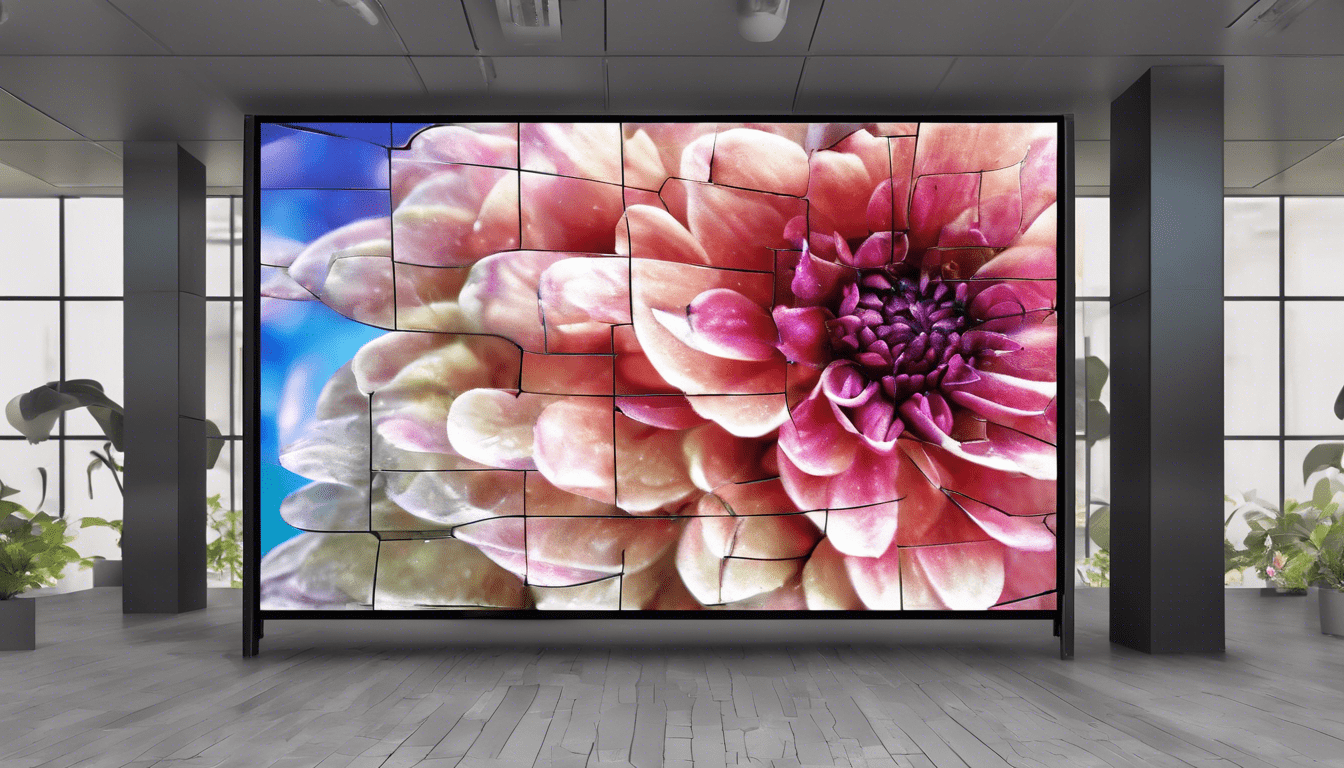

Introduction to LED Display Walls

As industries evolve and technology advances, LED display walls have become a cornerstone in digital signage, event management, and corporate presentations. This comprehensive guide will walk you through the intricate process of LED Display Wall Manufacture, from raw materials to the final product.

What is an LED Display Wall?

An LED display wall is a large visual display unit composed of multiple LED panels seamlessly connected to provide a larger and clear picture. Their applications range from advertising to virtual presentations, making them indispensable in today’s technology-driven world.

Applications of LED Display Walls

- Advertising and Marketing

- Event and Concert Displays

- Corporate Office Presentations

- Control Rooms and Surveillance

- Educational Institutions

Components of LED Display Walls

Understanding the components involved in LED Display Wall Manufacture can give you a better sense of their complexity and efficiency.

- LED Modules: Basic building blocks of the display

- Controller Cards: Manage the data processing

- Power Supply Units: Ensure stable power distribution

- Cabinets: Contain and protect LED panels

- Connectors and Cables: Facilitate communication and power flow

The Manufacturing Process

The process of manufacturing an LED display wall is intricate and involves numerous steps. Each phase is crucial in ensuring the end product is of high quality and durability.

1. Sourcing Raw Materials

High-quality raw materials are the foundation of a reliable LED display wall. Key components include semiconductors, metals, and plastics.

2. LED Module Production

This step involves mounting LEDs on a printed circuit board (PCB) and then integrating them into modules. Automated machinery often handles this to ensure precision.

3. Assembling Cabinets

The cabinets are assembled to house the LED modules. They are designed to be robust and durable, often made from aluminum or steel.

4. Installation and Testing of Controller Cards

Controller cards are installed within the cabinets to manage data and power distribution. Each card is rigorously tested to ensure it meets the required specifications.

5. Calibration and Quality Control

Calibration is critical to maintaining color accuracy and brightness. Quality control teams rigorously test each LED display wall for defects and performance issues.

Case Studies: Successful LED Display Wall Implementations

Several leading brands have implemented LED display walls successfully, enhancing their market presence and operational efficiency.

Times Square, New York

One of the most iconic uses of LED display walls is in Times Square, where numerous advertising screens captivate millions of visitors annually.

NASA Control Room

NASA utilizes LED display walls for monitoring and control, ensuring precise and clear information dissemination during critical missions.

Future Trends in LED Display Wall Manufacture

The future of LED display walls looks promising, with trends focusing on higher resolutions, flexible displays, and energy efficiency.

Ultra-High Definition (UHD)

As demand for clearer images grows, manufacturers are focusing on UHD technology, allowing for stunning visual experiences.

Flexible LED Displays

Flexible LED displays are becoming a reality, allowing more creative and adaptable designs, ideal for innovative architectural features.

Sustainable Practices

Manufacturers are leaning towards eco-friendly practices by utilizing recyclable materials and energy-efficient components.

How to Choose the Right LED Display Wall Manufacturer

Selecting the right manufacturer is crucial for a successful project. Here, we outline some key considerations:

- Experience and Reputation: Look for manufacturers with a proven track record.

- Quality Certifications: Ensure the company meets industry standards and certifications.

- Customer Support: Robust after-sales support can save you significant time and hassle.

- Customization Options: Tailored solutions can better meet your unique needs.

Conclusion

This guide has covered every aspect of LED Display Wall Manufacture, from materials to future trends. Whether you are looking to integrate an LED display wall for commercial or personal use, understanding the complexities behind its manufacture can help you make informed decisions.