Comprehensive Guide to China LED Matrix Display Factory

Introduction

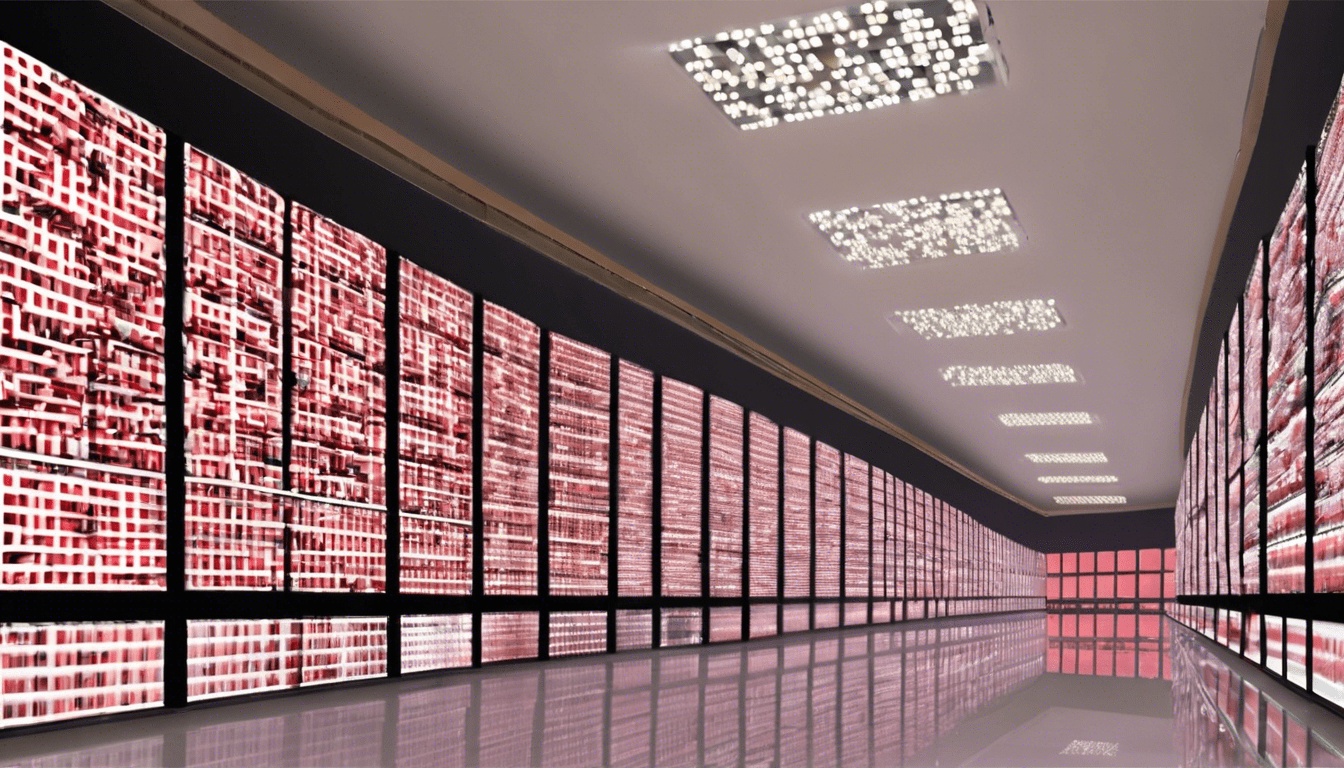

In the modern era, LED matrix displays have become an integral part of digital media and signage. When it comes to manufacturing high-quality LED matrix displays, the significance of a reliable factory cannot be overstated. This comprehensive guide delves into everything you need to know about China LED Matrix Display Factory, covering various aspects from production processes to quality standards.

What is an LED Matrix Display?

An LED matrix display is a type of digital display that uses light-emitting diodes (LEDs) arranged in a grid format to display images, videos, and texts. These displays are popular in advertising, information dissemination, and various digital art forms. LEDs offer superior brightness, energy efficiency, and longevity compared to traditional display technologies.

Components of LED Matrix Displays

- LEDs: The core components that emit light.

- Driver ICs: Integrated circuits that control the operation of LEDs.

- PCB: Printed circuit boards that house the LEDs and ICs.

- Power Supply: Provides the necessary electrical power to the display.

- Control System: Hardware and software that manage the overall display operation.

Why China is a Leading Manufacturer of LED Matrix Displays

China has established itself as a global leader in the production of LED matrix displays. Several factors contribute to this dominance:

1. Cost-Effectiveness

The cost of manufacturing in China is significantly lower compared to Western countries. Lower labor costs, efficient supply chains, and economies of scale play a crucial role.

2. Advanced Technology

Chinese factories are often equipped with state-of-the-art technology, enabling them to produce high-quality displays efficiently. Continuous investments in research and development further amplify their technological edge.

3. Skilled Labor

China boasts a vast pool of skilled labor adept at handling complex manufacturing processes. Rigorous training programs and vocational courses ensure a steady supply of skilled workers.

4. Strong Supply Chain

China’s robust supply chain enables quick sourcing of raw materials and components, reducing lead times and production costs. Numerous suppliers of electronics and related materials are based in the region, providing easy access to necessary components.

Key Features of a Reputable China LED Matrix Display Factory

When selecting a factory for LED matrix displays, several key features should be considered:

1. Quality Control Systems

A reputable factory will have stringent quality control systems in place to ensure each product meets high standards. This includes multiple testing phases, such as aging tests, waterproof tests, and brightness tests.

2. Certifications

Look for factories with recognized certifications such as ISO9001, CE, and RoHS. These certifications are indicators of adherence to international quality and safety standards.

3. Customization Capabilities

Leading factories offer extensive customization options. Whether you need specific pixel pitches, screen sizes, or unique display shapes, a top-notch factory will cater to your unique needs.

4. After-Sales Support

Quality after-sales support is crucial. This includes warranty services, technical support, and availability of replacement parts. Check for customer reviews or case studies that mention the after-sales services of the factory.

Production Process in a China LED Matrix Display Factory

Understanding the production process provides deeper insight into the complexities involved. Below is an overview of the typical production process:

1. Design and Prototyping

The process begins with designing and prototyping the display. Advanced CAD software is used to create detailed designs, which are then tested in prototype form for feasibility and performance.

2. Material Sourcing

The next step involves sourcing high-quality materials such as LEDs, ICs, and PCBs. Established relationships with suppliers ensure the materials meet quality standards and are delivered on time.

3. Assembly

In the assembly phase, the components are meticulously put together. This includes soldering LEDs onto PCBs, integrating driver ICs, and assembling the control system. Precision and accuracy are critical at this stage.

4. Testing

Once assembled, each display undergoes rigorous testing to ensure it meets quality specifications. This includes functional tests, durability tests, and environmental tests.

5. Packaging and Shipping

The final step involves securely packaging the displays and preparing them for shipment. Proper packaging ensures the displays are protected from damage during transit.

Applications of LED Matrix Displays

LED matrix displays are versatile and find applications across various industries:

- Advertising: Used in billboards, digital signage, and interactive displays.

- Transportation: Information displays in airports, train stations, and bus terminals.

- Events: Stage backgrounds, concert screens, and sports arenas.

- Retail: Point-of-sale displays, in-store promotions, and interactive kiosks.

- Public Information: Used by municipalities for announcements, public messages, and traffic information.

Choosing the Right China LED Matrix Display Factory

Given the myriad of options, selecting the right factory can be challenging. Here are some tips to help you make an informed decision:

1. Research

Conduct thorough research to identify potential factories. Look for reviews, industry reports, and case studies.

2. Factory Audit

Whenever possible, conduct a factory audit. This will give you firsthand insight into their processes, facilities, and quality control measures.

3. Quality Assurance

Ensure the factory has robust quality assurance protocols. Ask about their testing procedures and certifications.

4. Cost-Effectiveness

While cost should not be the sole determining factor, it’s essential to balance quality and affordability. Request detailed quotes and compare them to ensure you’re getting value for your money.

5. Communication

Effective communication is crucial. Assess the factory’s responsiveness and willingness to assist you. Good communication can significantly impact the overall project success.

Conclusion

China LED Matrix Display Factories are at the forefront of producing high-quality, cost-effective displays used globally. Their advanced technology, skilled labor, and robust supply chain make them reliable partners in the digital display industry. By understanding the key features and production processes, you can make informed decisions when selecting a factory for your LED matrix display needs.