Everything You Need to Know About Flexible Outdoor LED Display Panel Manufacture

Introduction to Flexible Outdoor LED Display Panels

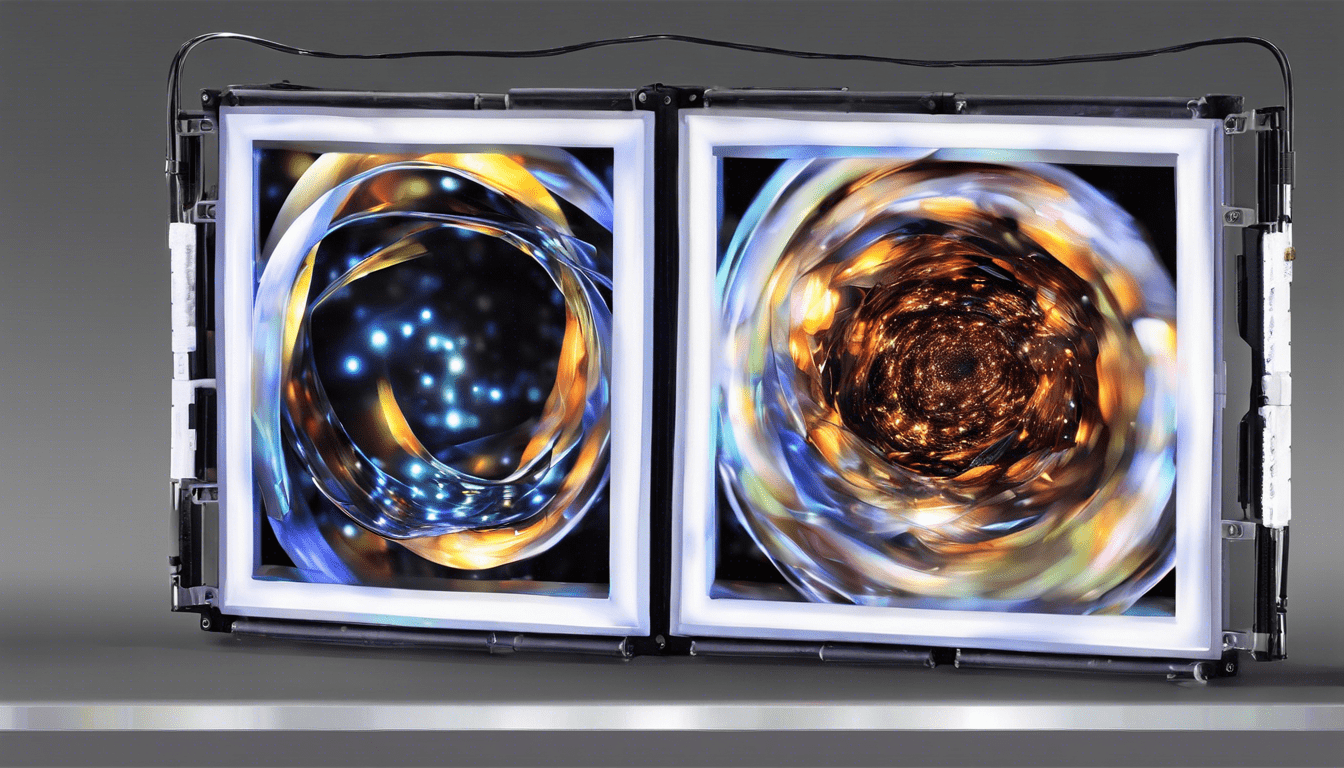

Flexible outdoor LED display panels are revolutionizing the way we advertise and broadcast information in public spaces. With their ability to curve around structures and offer vibrant imagery in all weather conditions, these high-tech displays are quickly becoming a staple in urban and event settings worldwide.

What is a Flexible Outdoor LED Display Panel?

- Definition: A flexible LED display panel is a type of light-emitting diode display that is adaptable to different shapes and curves.

- Key Features: Flexibility, weather resistance, high brightness, lightweight, and energy efficiency.

- Common Uses: Outdoor advertising, stadium screens, event stages, and urban installations.

Advantages of Using Flexible Outdoor LED Display Panels

Durability and Weather Resistance

Flexible LED panels are designed to endure harsh weather conditions, making them perfect for outdoor installations. They are made from robust materials that can withstand heavy rain, snow, wind, and even the occasional impact.

Energy Efficiency

LED technology is known for its low power consumption. This trait makes flexible outdoor LED displays an energy-efficient option that can significantly reduce operational costs over time.

High Brightness and Resolution

The advanced technology used in these panels ensures high brightness and high-resolution images, making them visible even in broad daylight.

Steps Involved in the Manufacture of Flexible Outdoor LED Display Panels

1. Design and Planning

The first step in manufacturing a flexible LED display panel is the design phase. During this stage, engineers and designers create a blueprint that outlines the dimensions, pixel pitch, and the curvature needs of the panel.

2. Selection of Materials

Choosing the right materials is crucial. Components typically include flexible PCBs (Printed Circuit Boards), top-grade LED chips, protective coverings, and waterproof connectors.

3. PCB Fabrication

Once materials are selected, the next step is fabricating the flexible PCB. This involves processes like etching, drilling, and layering to create a board that can bend and flex without breaking.

4. Soldering the LED Chips

The LED chips are then carefully soldered onto the PCB. Advanced machinery is used to ensure precision and minimize the chances of malfunction.

5. Assembly of Modules

Individual LED modules are assembled and grouped into larger panels. These modules are tested for brightness, color accuracy, and consistency before moving to the next stage.

6. Waterproofing and Sealing

Waterproof layers are added to the panel to make it weather-resistant. Sealing compounds are used to ensure that no moisture can penetrate the delicate electronics.

7. Quality Testing

Each panel undergoes a rigorous quality testing phase. Tests are conducted for brightness, color accuracy, weather resistance, and structural integrity.

8. Final Assembly and Installation

After passing all quality checks, the flexible LED display panels are subjected to final assembly. They are then packaged and shipped to clients for installation.

Technological Innovations in Flexible Outdoor LED Display Panel Manufacture

Innovations such as AI integration, IoT-enabled displays, and smart lighting controls are continually advancing the capabilities of flexible LED display panels.

Challenges in Manufacturing Flexible Outdoor LED Display Panels

Material Costs

The high cost of quality materials can be a significant barrier. However, investment in top-grade materials ensures durability and performance.

Technical Expertise

Manufacturing flexible panels require specialized skills and knowledge. Companies must invest in training and retaining skilled workers to maintain high standards.

Quality Control

Ensuring that each panel meets stringent quality standards is essential. Even a small defect can lead to catastrophic failures, making rigorous QC indispensable.

Market Trends in Flexible Outdoor LED Display Panels

Currently, the demand for curved and 3D LED displays is on the rise. Innovations in smart city infrastructure and public safety displays are also driving the market forward.

Case Studies

Times Square, New York

The use of flexible outdoor LED displays in Times Square showcases how these technologies can transform urban spaces. The eye-catching visuals draw millions of tourists, making it a hub of commercial activity.

Car Racing Tracks

Flexible LED displays at car racing tracks like Formula 1 circuits provide real-time updates and advertising, enhancing viewer experience and engagement.

How to Choose the Right Manufacturer

- Experience and Reputation: Choose a manufacturer with a proven track record in producing high-quality flexible LED display panels.

- Technology and Innovation: Ensure they invest in the latest technologies and continually innovate.

- Customer Support: Opt for companies that offer excellent customer support and after-sales service.

- Quality Assurance: Make sure they have rigorous quality control processes in place.

Conclusion

The manufacture of flexible outdoor LED display panels involves advanced technologies, quality materials, and precise processes. As demand for such displays rises, understanding the intricacies of their manufacture can help businesses make informed decisions when selecting a product that meets their advertising and broadcasting needs.