The Ultimate Guide to LED Glass Display Manufacture

Introduction to LED Glass Display Manufacture

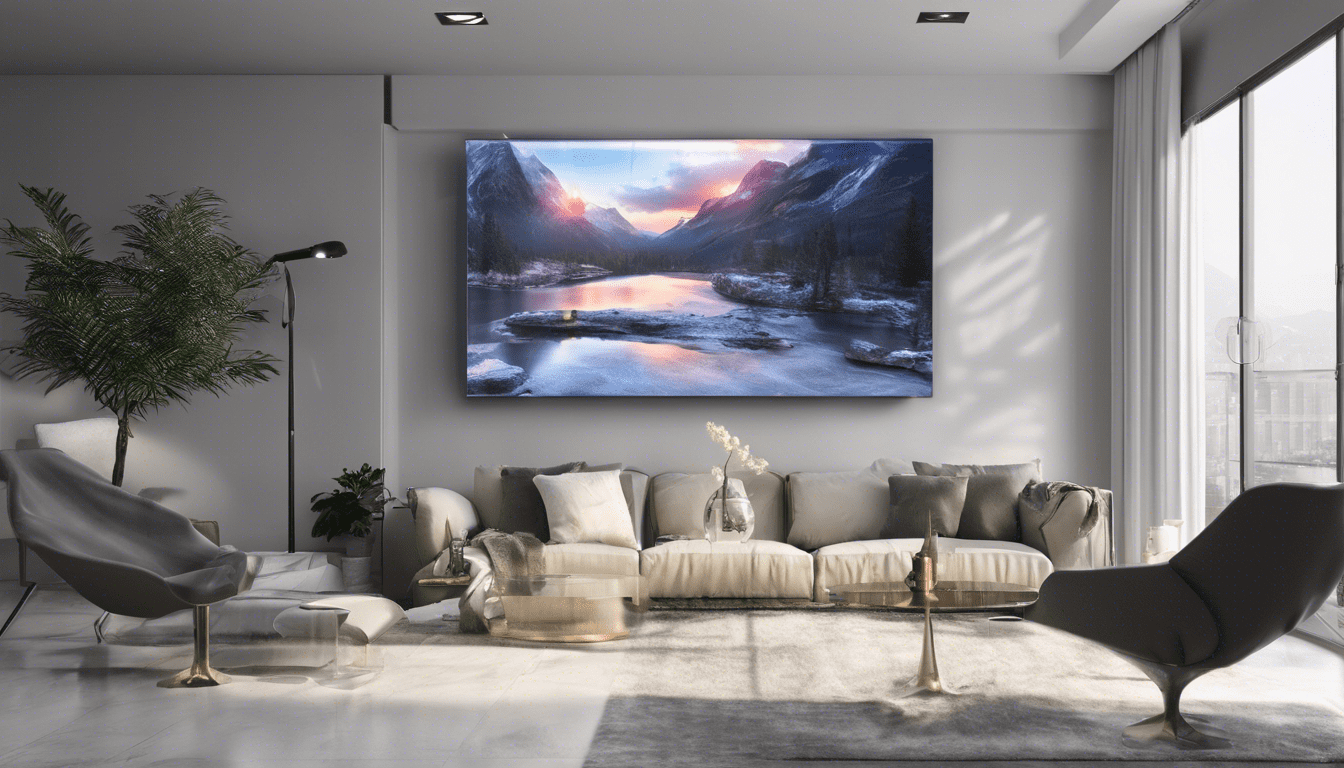

LED glass displays are at the forefront of modern visual technology, offering transparent screens combined with vibrant LED lights to produce striking visual effects. In this comprehensive guide, we’ll delve into the intricate world of LED glass display manufacture, from the materials used to the manufacturing process, and the various applications of these displays. Whether you’re a tech enthusiast or a business looking for cutting-edge display solutions, this guide is designed to provide all the information you need.

What is LED Glass Display?

LED glass displays involve embedding LED lights within the glass. This technology allows for the creation of transparent screens that can display images and video without obstructing the view through the glass. These displays are commonly used in advertising, retail, architecture, and entertainment sectors.

Key Components of LED Glass Displays

- LED Lights: The primary source of illumination.

- Glass Panels: High-quality glass that houses the LED lights.

- Control Systems: Mechanisms to manage the lighting and display features.

Materials Used in LED Glass Display Manufacture

In manufacturing LED glass displays, precision and quality of materials play a critical role. Here are some of the essential materials involved:

- High-Grade Glass: The transparency and strength of the glass are vital. Commonly, tempered glass or laminated glass is used.

- LED Chips: These chips are the core components that emit light, varying in color and intensity.

- Conductive Film: To connect lights and ensure the display functions seamlessly.

- Adhesives and Sealants: For durability and longevity, ensuring the LEDs are firmly attached and protected.

The Manufacturing Process of LED Glass Displays

The manufacturing process of LED glass displays requires precision and expertise. Here’s a step-by-step breakdown of the entire process:

1. Design and Planning

Before any physical work begins, a detailed design is crafted. This design includes dimensions, LED placement, and technical specifications, tailored to the client’s needs.

2. Glass Cutting and Shaping

A precise cutting and shaping process is conducted for the glass panels to fit the design. High-precision tools ensure smooth edges and accurate measurements.

3. Embedding LED Lights

LED lights are embedded into the glass panels, usually through a conductive film. This step requires meticulous attention to detail to ensure uniformity and proper function.

4. Sealing and Adhesion

Specialized adhesives and sealants are applied to secure the LED lights within the glass panels, providing durability and protection against external elements.

5. Testing and Calibration

Once assembled, each LED glass display undergoes rigorous testing. Any inconsistencies in light output or potential defects are addressed to ensure the final product meets high-quality standards.

6. Final Assembly

All components are assembled, including the control systems and mounting fixtures. The final product is then ready for packaging and shipment.

Applications of LED Glass Displays

LED glass displays are versatile and find applications across various industries:

Retail and Advertising

These displays enhance store aesthetics and attract customers by displaying dynamic visual content.

Architecture

In modern architecture, LED glass is used for building facades, adding a futuristic look to any structure.

Entertainment

From concerts to art installations, LED glass displays create immersive experiences with minimal obstructions.

Advantages of LED Glass Displays

Several benefits make LED glass displays a preferred choice:

- High Transparency: Provides clear views while displaying content.

- Energy Efficient: LED technology is known for low power consumption.

- Durability: High-quality materials ensure longevity.

- Customization: Flexible design options to meet unique needs.

Choosing a LED Glass Display Manufacturer

When selecting a LED glass display manufacturer, consider the following factors:

- Experience and Expertise in the Industry

- Quality of Materials Used

- Client References and Testimonials

- Customization Capabilities

- Post-Sales Support and Maintenance Services

Future Innovations in LED Glass Display Technology

The field of LED glass display manufacture is continually evolving. Emerging trends include:

- Smart Glass Integration: Combining LED displays with smart glass technology for dynamic control.

- Advanced OLED Integration: Enhancing display quality with OLED technology.

- Sustainable Manufacturing: Focus on eco-friendly materials and processes.

Conclusion

As technology continues to advance, the LED glass display manufacture industry is poised for significant growth. With their unparalleled transparency, energy efficiency, and customizability, LED glass displays are an excellent investment for businesses and innovators looking to stay ahead of the curve.